Energy storage inverters play a key role in managing electricity in industrial workplaces. They change direct current (DC) from storage units into alternating current (AC) that machines need. In solar power systems, these devices turn DC from panels into AC for grid or factory use. This supports steady energy flow with little waste. Also, inverters keep power stable by fixing disruptions. They provide a reliable energy supply, which is necessary for ongoing work.

How Do Energy Storage Inverters Optimize Energy Usage?

How Do Energy Storage Inverters Optimize Energy Usage?

Energy storage inverters boost power efficiency by handling stored energy smartly. They pair well with renewable sources like wind or solar. Extra energy is kept when output is high. This saved power is used later during busy times. For example, inverters rely on passive parts that stay strong and reliable for long periods. Such systems cut down on grid use. They also help factories meet eco-friendly targets.

Energy storage inverters bring strong benefits to factories. They improve workflow by avoiding stops from power failures or changes. Plus, they lower costs. Plants can use stored energy during pricey peak hours. In uninterruptible power supply (UPS) systems, inverters ensure safe equipment and computer shutdowns during blackouts. They also fill gaps until backup power kicks in. Using parts like DC Link Capacitors (e.g., MKP-LM Series), which balance and filter DC, makes production steadier and more dependable.

Without good energy storage, industries risk problems from unsteady power. Quick voltage jumps or drops can harm tools. They may also slow work and raise safety concerns. These issues are toughest in fields needing constant, high energy.

Wasting energy increases expenses. Bigger power bills come from poor use. Factories might also face charges for going over grid limits. Without storage, renewable energy made during slow times is lost.

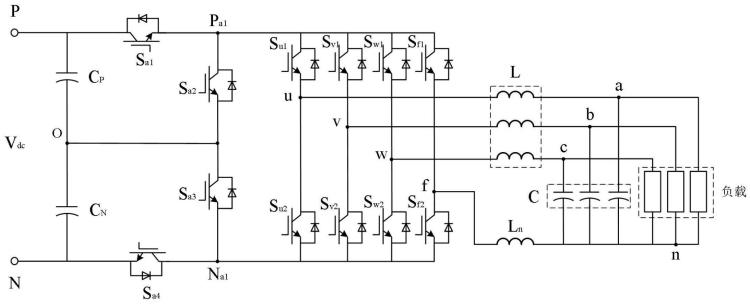

Energy storage inverters fix these problems by supplying even power. They work well despite outages or dips. Plants can save surplus renewable energy and use it thoughtfully. This reduces grid reliance. Special capacitor technologies, like Snubber Capacitors (e.g., MKP-R Series), protect IGBT modules from voltage surges. These parts strengthen systems. Inverters also refine power quality. They use filters to correct harmonic issues.

Fields like car manufacturing, steel making, and chemical production need lots of power. Energy storage inverters provide steady electricity during high-demand periods. For instance, car charging stations with DC fast charging use efficient inverters. These deliver quick power with low energy loss.

As countries aim for carbon neutrality by 2050, renewable energy is a top focus. Solar systems with storage depend on solid inverters to turn DC from panels into AC. These setups often include AC Filter Capacitors (e.g., MKP-AM Series) for output filtering. Such parts ensure stable work across factory tasks.

Places like hospitals, data centers, and research labs can't handle power breaks. Energy storage inverters offer safety through UPS systems. These maintain electricity flow. Capacitors in AC-DC rectifiers and DC-AC inverter stages keep systems trustworthy in all cases.

SMILER leads in energy storage inverters with smart solutions. As nations target carbon neutrality by 2050, switching from fossil fuels to renewables is vital. SMILER supports this with advanced power electronics. Its tools improve energy creation, storage, and conversion. The company's metalized film capacitors make inverters more efficient and lasting.

Advanced Capacitor Integration for Improved Performance

SMILER's inverters excel with unique capacitors. The DC Link Capacitor (MKP-LM Series) manages DC filtering and smoothing. With capacitance from 1μF to 170μF and voltages from 450V to 1200Vdc, these capacitors steady solar systems. Such setups need passive parts with high stamina over time. The MKP-LM Series meets this demand.

SMILER also uses Snubber Capacitors (MKP-R Series). These guard IGBT modules against voltage spikes. With capacitance from 0.033μF to 3.0μF and voltages from 850V to 2000Vdc, they toughen systems during heavy work.

Customizable Solutions for Diverse Industrial Needs

SMILER provides adaptable tools for varied industries. Its inverters aid renewable energy use and improve power quality in plants. For example, AC Filter Capacitors (MKP-AM Series) are made for output filtering in UPS systems and EV charging stations. With capacitance from 0.47μF to 50μF and voltages from 160V to 450Vac, they keep operations smooth.

High Reliability and Durability Standards

SMILER builds products with dependability in mind. In UPS systems, sturdy parts are crucial. These systems balance power during disruptions or blackouts. SMILER uses tough capacitors, like Snubber and DC Link Capacitors, at key spots like AC-DC rectifiers and DC-AC inverter stages. This ensures steady performance in hard settings.

SMILER's inverters perform well in diverse projects:

1. Photovoltaic Systems: In solar farms, SMILER's DC Link Capacitors balance voltage in booster circuits. This aids in clean DC-to-AC conversion for grids.

2. Wind Energy Projects: AC Filter Capacitors steady energy output under shifting wind speeds.

3. Electric Vehicle Charging Stations: Snubber Capacitors shield IGBT modules in DC fast-charging systems. These provide fast power for long drives.

4. Industrial UPS Systems: Data centers rely on SMILER's capacitor tools for constant power during outages.

These examples show SMILER's impact on stability and efficiency in many fields.

Q: What is the primary function of an energy storage inverter?

A: It turns direct current (DC) from batteries or renewables into alternating current (AC) for factory or grid use.

Q: How do energy storage solutions benefit renewable energy integration?

A: They save excess energy during high output and use it during peak demand, improving resource use.

Q: Can energy storage inverters help reduce electricity costs?

A: Yes, they let factories use stored power during costly peak times, cutting grid expenses.

Q: What types of capacitors are commonly used in inverter systems?

A: DC Link Capacitors (for filtering), Snubber Capacitors (for IGBT protection), and AC Filter Capacitors (for output smoothing) are vital parts.

Q: Why are UPS systems important for critical facilities?