Resistors are used in electrical circuits due to the consideration that they regulate the flow of currents and voltages in the circuit system effectively. In particular, in DC circuits where they regulate the current flow to other areas of the circuit to prevent overloading and enable efficient flow to other equipment by converting electricity into heat. Resistors also ensure circuit action stabilizes by limiting voltage drops and heat dissipation, which are necessary for devices that experience thermal variations. In systems like zero-resistance ammeters, resistors balance precision and safety, ensuring accurate measurements without compromising insulation integrity.

Capacitors work by storing energy temporarily in an electric field between their plates when connected in parallel in a DC circuit – this causes them to display distinct behaviors that influence the circuits performance greatly. The total capacitance of capacitors increases in setups as the individual capacitances are combined together. This uptick enables capacitors to store more charge and better handle changes in voltage levels.

Capacitors work by storing energy temporarily in an electric field between their plates when connected in parallel in a DC circuit – this causes them to display distinct behaviors that influence the circuits performance greatly. The total capacitance of capacitors increases in setups as the individual capacitances are combined together. This uptick enables capacitors to store more charge and better handle changes in voltage levels.

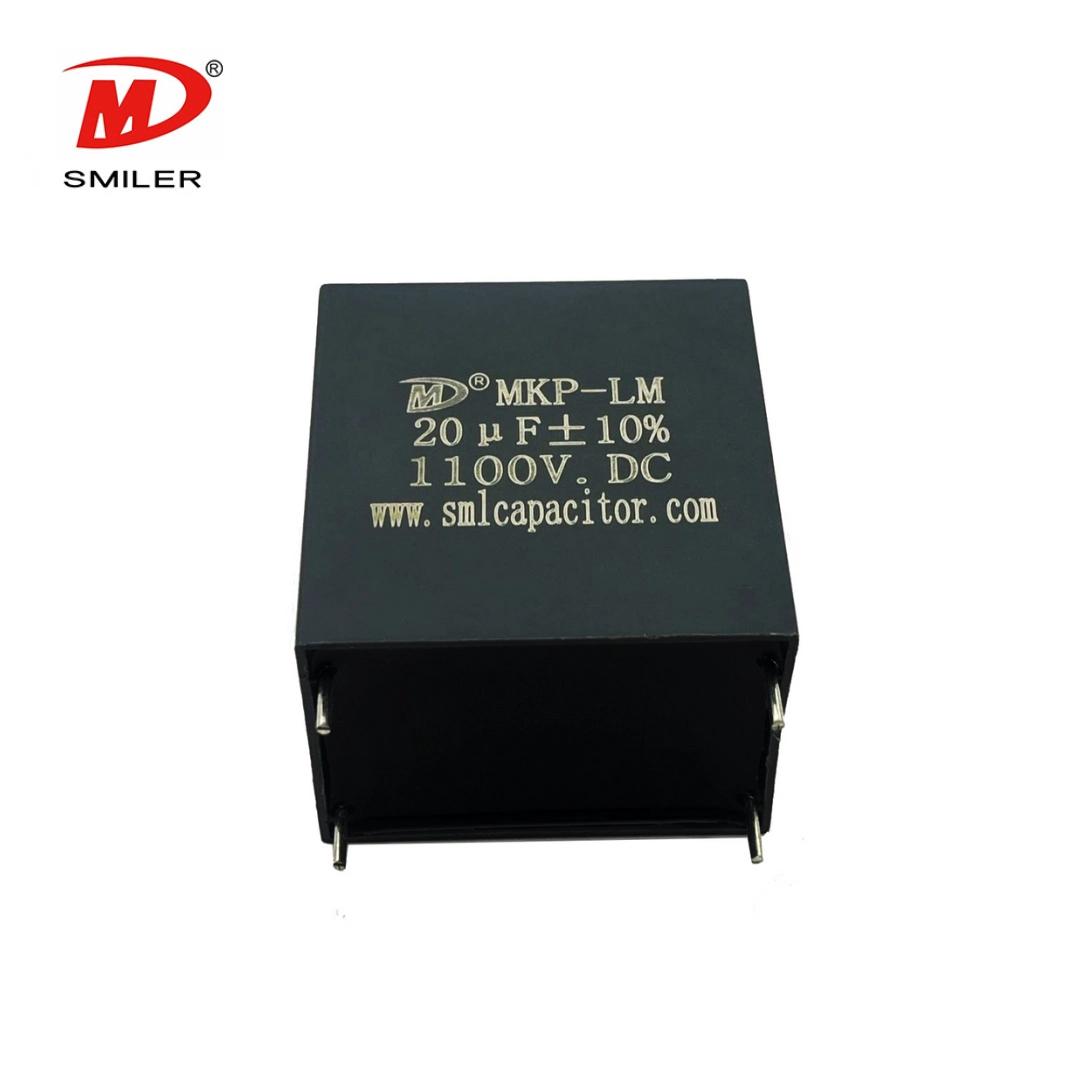

Unlike resistors, capacitors do not dissipate energy. Instead, they release stored energy when required by the circuit. In a DC circuit specifically, capacitors initially allow current to flow as they charge up but eventually block direct current once fully charged. This property makes them invaluable for applications requiring filtering or smoothing of voltage signals. The DC Link MKP-LM has an excellent over voltage and over current capability. Its medium is metallized polypropylene film and filled with resin.

Once the resistor and capacitor are paralleled in a DC circuit system, they join forces together and control the current flow, along with stabilizing the voltage level efficiently. The resistor offers a current path and allows the excess energy to be dissipated in the form of heat. At the time, the capacitor maintains stable voltage levels by storing and releasing charge as required.

This blend of features is useful in industries, such as the DC Link MKP-LL capacitors that are tailored for DC link circuits to substitute conventional electrolytic capacitors effectively. The capacitors exhibit ESR levels and excel at managing ripple currents while possessing self-repair capabilities. This is where their strength lies in applications, including welders and elevators as well as motor driver systems.

The use of polypropylene film enhances durability and ensures top-notch performance across different conditions. Engineers can enhance performance for purposes, such as noise filtering at high frequencies or voltage stabilization by combining these elements in parallel configurations with resistors.

Optimizing parallel DC circuits ensures balanced current distribution and minimizes energy loss, directly enhancing system efficiency. Selecting components like resistors, capacitors or diodes with precision prevents uneven power dissipation, reducing heat generation and voltage drops.

Designing parallel DC circuits presents several challenges that require careful consideration during the planning phase. One common issue is balancing component values to achieve desired performance without introducing unnecessary complexity or cost. For instance, mismatched resistor values can lead to uneven current distribution across branches of the circuit.

One more obstacle is dealing with heat dissipation efficiently in setups that include resistors and capacitors as too much heat can diminish the performance of components, unless the right thermal management techniques are put in place.

One more obstacle is dealing with heat dissipation efficiently in setups that include resistors and capacitors as too much heat can diminish the performance of components, unless the right thermal management techniques are put in place.

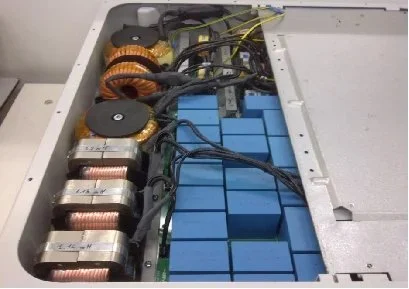

SMILER uses unique capacitor designs customized for challenging uses such as EV rapid chargers or solar inverter systems. The further expansion of photovoltaics is a central core element of the energy transition. In addition, the need to balance supply and demand will result in increasing demand for storage systems (ESS), both in the domestic sector and on an industrial scale. These systems require inverters to convert the direct current generated by the photovoltaic system into alternating current so that the energy can be fed into the grid or into one’s own household. Inverters require passive components with the highest reliability and resilience with long operating times.

SMILER is widely recognized for its performance in the resistor and capacitor industry which focuses on parallel DC circuit applications. They demonstrate a dedication to quality through their advanced automated production lines that prioritize efficiency and accuracy. These facilities streamline production processes while maintaining quality standards resulting in a success rate of over 99.93 %.

SMILER resistors are truly remarkable in their design and function. They are crafted with precision to control the flow of current efficiently in parallel DC circuits to avoid any overload while keeping the voltage stable. Their use of high-quality materials and advanced manufacturing techniques guarantees their dependability in challenging situations. Whether they are incorporated into energy setups or utilized in industrial machinery such as welding tools and elevators. SMILER’s resistors deliver reliable performance that adheres to top-notch industry norms.

SMILER has built a reputation as a reliable partner for global industries by consistently providing top-quality components that tackle specific issues in parallel DC circuits effectively. For example, their capacitors are essential in energy setups as they help stabilize voltage levels and filter out noise resulting from fluctuating power generation activities. Particularly in wind and solar power inverters to ensure energy production even in changing environmental circumstances.

SMILER’s expertise is also valuable in settings where their resistors play a crucial role in maintaining accurate current control in welding machines and elevators to avoid system malfunctions from the uneven current distribution. Additionally, their capacitors with self-healing capabilities boost reliability by averting disasters triggered by dielectric breakdown incidents.

A: It amplifies the voltage. The circuit acts as an open circuit.

A: Ideal resistors are non-inductive, and they also do not have capacitive components. So really it should not matter whether they are used for DC or AC, performance in both cases will remain same.

A: A capacitor only allows the flow of alternating current but not direct current whereas resistor and inductor allow the flow of ac as well as dc through them.

A: The resistor provides a route for discharging the capacitor when the DC power is switched off. Otherwise, the capacitor could retain a charge indefinitely, which could cause safety problems (e.g., unanticipated discharge). The resistor ensures controlled energy release, stabilizing voltage decay.

A: The resistor determines the discharge time constant (τ= RC). A smaller resistor accelerates discharge but increases power loss during operation. In high-reliability systems, balancing resistor values minimizes heat (avoiding capacitor degradation) while ensuring safe discharge as abrupt voltage drops can damage components.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Exploring How AC Capacitors and DC Capacitors Function Differently

Understanding Snubber Capacitor: RC vs. RCD Snubber Differences

Understanding DC Capacitance to Prevent Converter Oscillations

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors