A DC link capacitor does a super important job in an electric vehicle’s (EV) inverter system. It evens out the DC voltage sent to the inverter. This keeps power flowing to the motor nice and steady. The capacitor works in DC-link circuits and can replace electrolytic capacitors. It has low Equivalent Series Resistance (ESR). It handles high ripple currents really well. Plus, it has self-fixing features. These traits help the inverter turn direct current (DC) from the battery into alternating current (AC) for the motor.

In EVs, where awesome performance and dependability are a big deal, the DC link capacitor acts like a go-between. It sits between the battery and the inverter. It holds energy for a short bit. This helps manage voltage shifts when the motor needs power fast. So, it keeps delicate electronic parts safe. It also makes the whole system run better.

Steady voltage is super necessary for EV systems to work smoothly. The DC link capacitor helps a ton by cutting down on voltage ripple. Ripple is a hiccup caused by the inverter’s switching actions. The capacitor’s ability to handle high ripple currents keeps these bumps small. This gives a stable voltage to other parts.

Also, its low stray inductance (Ls) makes it even better at keeping voltage steady. It reduces high-frequency noise and sudden voltage spikes. This protects important parts like insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) modules in modern EVs. These efforts make things more efficient. They also help parts last longer.

Adding a DC link capacitor to an EV inverter really boosts system efficiency. It smooths out bus voltages. It keeps power modules safe from overvoltage issues. This cuts down on energy waste from voltage swings. It’s really important during quick acceleration or braking. That’s when power needs change fast.

Plus, its self-fixing feature keeps it reliable in tough situations. For example, capacitors made with metallized polypropylene film handle overvoltage and overcurrent super well. They also pack lots of capacitance in small sizes. These qualities make them perfect for EVs. Space is often limited in these vehicles.

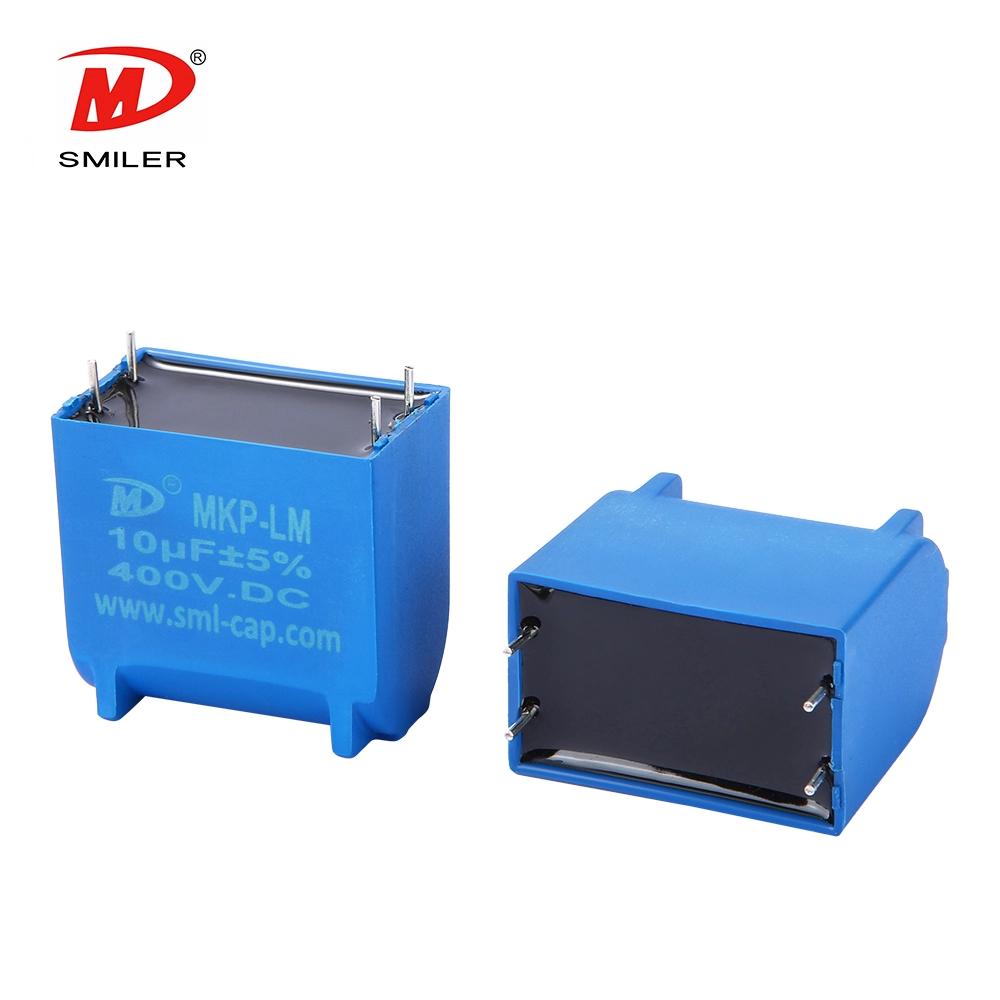

Today’s EVs need parts that can handle huge power demands without messing up performance or safety. Advanced DC link capacitors do this really well. Capacitors like the MKP-LM series have tons of capacitance in small packages. They stay reliable in rough conditions, like high humidity or hot weather.

These capacitors also support high switching frequencies in next-gen EV inverters. They handle higher frequencies without big losses. This leads to faster response times. It also gives better control over motor actions. Plus, they work in wide temperature ranges, from -40°C to +105°C. This means they perform great no matter the weather.

For instance, think of a 30kW power inverter in an EV. A matching bus film capacitor with 330μF capacitance, 500V rated voltage, and low stray inductance (<10nH) works awesome. It meets strict reliability needs. It also delivers top performance.

In short, DC link capacitors are super key in EV inverter design. They stabilize voltage. They cut ripple. They boost efficiency. And they handle big power demands. These traits make them vital for strong and reliable EV performance.

Choosing the right DC link capacitor for inverters means checking its voltage ratings and capacitance needs. These things directly affect how well the inverter system works. They also impact its reliability. The capacitor’s rated voltage must be higher than the system’s top voltage. This prevents breakdown or damage. For example, capacitors with voltage ranges from 600Vdc to 4000Vdc are common in high-performance inverters. They handle the changing needs of EV systems.

Capacitance matters a lot. It decides how much energy the capacitor can hold and release. More capacitance helps smooth out voltage changes better. Capacitors with capacitance from 24μF to 5600μF fit various needs. But, you gotta balance energy storage with size limits. This is especially true in small EV designs.

Thermal management is a huge factor when picking a DC link capacitor. Capacitors make heat during operation because of internal resistance. Too much heat can hurt performance. It can also shorten lifespan. Good heat control is key to keeping things running smoothly. Capacitors made with metallized polypropylene film have great thermal stability. They’re also super tough. Their operating temperature range should match the application’s conditions. Some work awesome from -40°C to +85°C. Others go up to +105°C for certain designs.

Toughness factors are also important. These include handling high ripple currents, overvoltage, and physical stress. Self-fixing features make capacitors more reliable. They let capacitors recover from small dielectric breakdowns without losing performance. These qualities make them perfect for tough jobs like EV inverters. Steady performance is a must in these systems.

SMILER’s DC link capacitors are built for awesome reliability and long life. Our automated production lines follow strict quality rules. We achieve a qualified finished product rate above 99.93%. This means every capacitor meets high performance standards before reaching customers.

SMILER’s DC link capacitors are built for awesome reliability and long life. Our automated production lines follow strict quality rules. We achieve a qualified finished product rate above 99.93%. This means every capacitor meets high performance standards before reaching customers.

Using metallized polypropylene film as the dielectric, DC Link MKP-L gives strong electrical insulation. It also allows self-fixing traits. These make the capacitor last longer. They also keep it safe by preventing big failures during operation. SMILER capacitors use sturdy materials like aluminum shells or plastic cases with resin filling (UL94 V-0). These stand up to things like humidity and temperature shifts.

SMILER’s capacitors are fantastic at handling high ripple currents. Low Equivalent Series Resistance (ESR) cuts energy losses from high-frequency switching in inverters. This boosts efficiency. It also keeps heat low. This helps with thermal management.

Plus, these capacitors support high switching frequencies in modern EV systems. Their low stray inductance (Ls) keeps circuit interference low. This ensures stable voltage across different load conditions.

SMILER’s DC link capacitors are used a bunch in EV systems. Their smart design and flexible specs make them great. They’re perfect for power inverters, where efficient power conversion is a must. For example, the MKP-LM series offers lots of capacitance in small sizes. These capacitors handle overvoltage and overcurrent really well. They’re awesome for managing changing power demands in EVs.

SMILER’s DC link capacitors are used a bunch in EV systems. Their smart design and flexible specs make them great. They’re perfect for power inverters, where efficient power conversion is a must. For example, the MKP-LM series offers lots of capacitance in small sizes. These capacitors handle overvoltage and overcurrent really well. They’re awesome for managing changing power demands in EVs.

Beyond inverters, SMILER capacitors work in motor driver systems, welders, elevators, and renewable energy setups. These include wind or solar power converters. They stay reliable in extreme conditions. This ensures steady performance across different settings.

By using SMILER’s advanced DC link capacitors, you can improve efficiency, reliability, and performance in EV inverter designs. They handle modern automotive needs super well.

A: The DC link capacitor is a super important part in an electric vehicle’s (EV) inverter setup. It keeps voltage levels steady between the rectifier and inverter stages. This helps the system switch direct current (DC) to alternating current (AC) smoothly. The capacitor makes sure power flows nicely to the motor.

A: A DC capacitor has several jobs. It smooths out voltage ups and downs. It cuts down on ripple currents. It protects electronic parts from damage due to sudden voltage jumps or drops. Also, it boosts the system’s efficiency. These tasks make the EV run better.

A: Metallized polypropylene film capacitors are a top choice because they have low ESR. They handle high ripple currents super well. They also have self-fixing traits and last a long time. These capacitors work great in hot conditions. This makes them perfect for tough EV jobs.

A: A well-made DC link capacitor boosts powertrain efficiency. It cuts energy waste and keeps voltage steady. This helps the system use battery power more smartly. As a result, it can extend the EV’s driving range. Steady power delivery makes a big difference for drivers.

A: Several things matter when choosing a DC link capacitor. You need to check its voltage rating and capacitance value. Thermal management is a big deal too. Toughness features, like self-fixing traits, are super important. The capacitor should follow industry rules, like IEC 61071. It also needs to fit the specific needs of the application.