DC link capacitors are components in today’s electronics landscape especially in setups that demand effective energy conversion. DC link capacitance is the energy storage component in the DC link circuit of power electronic converters, e.g., inverters, motor drives or renewable energy converters. It acts as a buffer between the input (e.g., rectifier) and output (e.g., inverter) stages, stabilizing the DC bus voltage and filtering out high-frequency ripple currents generated during switching operations. For example, in EV inverters, DC link capacitors with low ESL (≤5nH) and high pulse current ratings (e.g., 30kA) are required to handle high-speed power transitions with voltage integrity.

The Role of DC Link Capacitors in Electronics

The Role of DC Link Capacitors in ElectronicsThe use of DC link capacitors mainly involves the bypassing of voltage fluctuations and offer a fixed DC power source for electronic circuits—an indispensable duty in usage such as DC-AC inversion from inverters used in AC consumption of electricity. DC link capacitors apply within DC link modules as replacements to capacitors given their capability in low ESR (Equivalent Series Resistance) management of large amounts of ripple current effectively while even self-healing inherent blemishes.

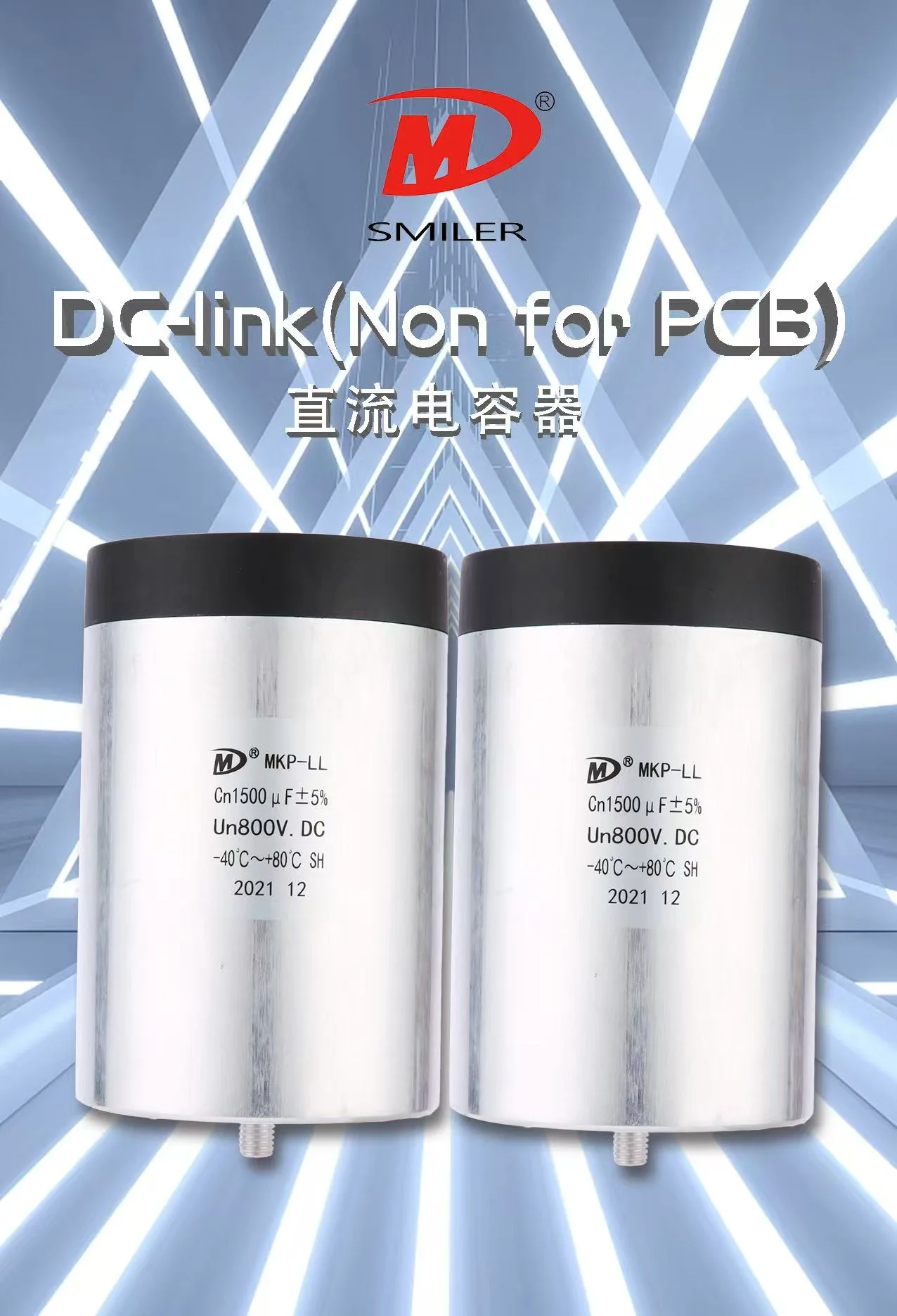

The special design of DC link capacitors makes them efficient and reliable. The DC Link MKP-LS is impressive in its use of polypropylene film in an aluminum housing filled with resin for insulation. It has a small product size and an excellent heat dissipation. The tinned copper terminals serve as its lead. These design elements are instrumental in ensuring longevity and consistent performance over time.

The effectiveness of systems is greatly influenced by the quality of the components utilized within them. The contribution of DC link capacitance in this case cannot be overstated.

SMILER’s DC Link MKP-LL capacitors are known for providing capacitance in a small size with high ruggedness for over-voltage stress to facilitate reliable functioning of applications such as frequency converters and high-power industrial systems. Further, low stray inductance (Ls) in the capacitors keeps voltage spikes from propagating to and destroying sensitive components. The self-healing property avoids small dielectric breakdowns from degrading the performance of the capacitor over its lifetime.

SMILER’s DC Link MKP-LL capacitors are known for providing capacitance in a small size with high ruggedness for over-voltage stress to facilitate reliable functioning of applications such as frequency converters and high-power industrial systems. Further, low stray inductance (Ls) in the capacitors keeps voltage spikes from propagating to and destroying sensitive components. The self-healing property avoids small dielectric breakdowns from degrading the performance of the capacitor over its lifetime.

Determining the value of capacitance for the DC link is critical to having the system up and running at its best level of performance, so you need to know what affects how you choose capacitors and make sure they are suitable for your specific application.

1. Voltage Rating: The capacitor should be in a position to handle the voltage it will receive when being utilized without issues. SMILER’s capacitors can come in numerous volts ranging from 200 volts through to 4000 volts.

2. Capacitance Rating: This is the amount of charge that may be held by the capacitor at any given moment. For example, SMILER has capacitance ratings ranging from 0.033μF to 5600μF depending on the model in question.

3. Ripple Current Management: High ripple currents cause excessive heating, hence low ESR is necessary.

4. The capacitor should work within the operating temperature for which it was designed: e.g., SMILER’s DC Link MKP-LL series that works between 40°C to 85°C or up to 80°C in larger capacitors.

5. Lifetime Expectancy Tip: Being able to work for its entire lifespan can minimize maintenance expenses and decrease downtime.

One of the frequent uses for inverters is when precise calculations are needed for the DC link capacitor to minimize voltage fluctuations and meet the load demands of the inverter.

The process usually includes figuring out how much energy storage is needed by using formulas that rely on system parameters, such as changes in input voltage and the current needed to operate the system efficiently. Moreover, it’s important to take into account factors like how switches are flipped and how heat is managed in the system.

SMILER’s DC link capacitors are designed to be highly reliable and durable to suit today's electronics industry in a right way. The capacitors have a medium of metalized polypropylene film and are packaged in durable aluminum or plastic cases with resin filling for insulation. This construction not improves their durability but also ensures they can withstand various environmental factors effectively.

The company uses technology in its production facilities to uphold high-quality standards consistently. The daily production capacity is 300,000 units with an impressive qualification rate of over 99.93%. SMILER ensures reliable performance throughout its product lineup. These capacitors undergo thorough testing to meet global standards, like GB/T 17702 (IEC 61071) emphasizing their dependability further.

SMILER distinguishes itself with its cutting-edge materials and creative design methods in the product range. The DC Link MKP-L series exemplifies characteristics such as ESR (Equivalent Series Resistance) excellent handling of ripple currents and the ability to self-heal. These qualities make them perfect for tasks that demand top-notch efficiency and extended lifespan in operation. Moreover, SMILER provides voltage options ranging from 600 volts to 4000 volts and capacitance values between 24μf and 5600μf which is crafted to endure high humidity scenarios without compromising on its exceptional resistance to over voltage and over current issues.

SMILER’s DC link capacitors find application in many advanced applications, such as inverters for renewable energy systems like wind power turbines and solar energy systems. They help in controlling voltage levels to facilitate efficient energy conversion and enhance the performance of the system.

SMILER’s DC link capacitors find application in many advanced applications, such as inverters for renewable energy systems like wind power turbines and solar energy systems. They help in controlling voltage levels to facilitate efficient energy conversion and enhance the performance of the system.

These capacitors are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) in the automotive industry. They are designed specifically to manage ripple currents and reduce stray inductance to prevent voltage spikes that can damage critical components in EV powertrains.

They are also used in transformer cabinets. DC capacitors in transformer cabinets primarily serve to stabilize voltage and filter electrical noise, enhancing system reliability.

When it comes to inverters that must operate under various environmental conditions SMILER’s capacitors are renowned for their superior reliability. Their ability to self-repair ensures a lifespan even when faced with frequent voltage changes.

When you opt for SMILER for your DC link capacitance requirements, you get to utilize technology that improves system efficiency and cuts down on maintenance expenses.

A: The DC Link Capacitor is among power electronics components used in inverters, converters, and motor drives. Although its primary role is to stabilize and regulate direct current (DC) voltage, it also senses any sudden changes in voltage in the DC link circuit.

A: In a dc circuit, a capacitor acts like an open circuit when it is fully charged or discharged. This means that no current flows through it. In an ac circuit, a capacitor acts like a resistor that depends on the frequency of the ac source. This means that the current through it varies with the frequency.

A: You can refer to this formula to simply calculate the capacitance C = Vbus / (32 ∗ L ∗ ΔV ∗ fpwm^2), the ΔV depends on voltage, current ripple and power.

A: ESR impacts efficiency and heat generation, especially at high frequencies. Low ESR reduces losses in fast-switching circuits. Temperature affects capacitance: at -40°C, low-voltage capacitors lose ~20% capacity, while high-voltage types lose ~40%. High temperatures degrade leakage current and DF, risking instability. Custom DC-Link designs prioritize thermal resilience and low ESR/ESL to maintain reliability in extreme conditions.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Exploring How AC Capacitors and DC Capacitors Function Differently

Understanding Snubber Capacitor: RC vs. RCD Snubber Differences

Understanding DC Capacitance to Prevent Converter Oscillations

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors