When you hook up a capacitor to a DC source, it acts like a short circuit at first. Current flows fast as it charges. But this changes quickly. Once the capacitor matches the DC supply's voltage, it turns into an open circuit. No more current flows. This makes capacitors different from resistors or inductors in DC setups.

As current goes into the capacitor, electrons pile up on one plate. They get pulled off the other plate. This builds an electric field across the dielectric stuff inside. The charge stored depends on the voltage and capacitance. But watch out. Charging and discharging too fast can overheat or damage the capacitor. So, good design is key to making it last.

Yup. Capacitors hold energy in an electrostatic field between their plates. You can figure out the energy with the formula E = ½CV². Here, C is capacitance, and V is voltage. Once charged by a DC source, capacitors keep this energy for a long time. They only lose it through an external load or tiny leaks.

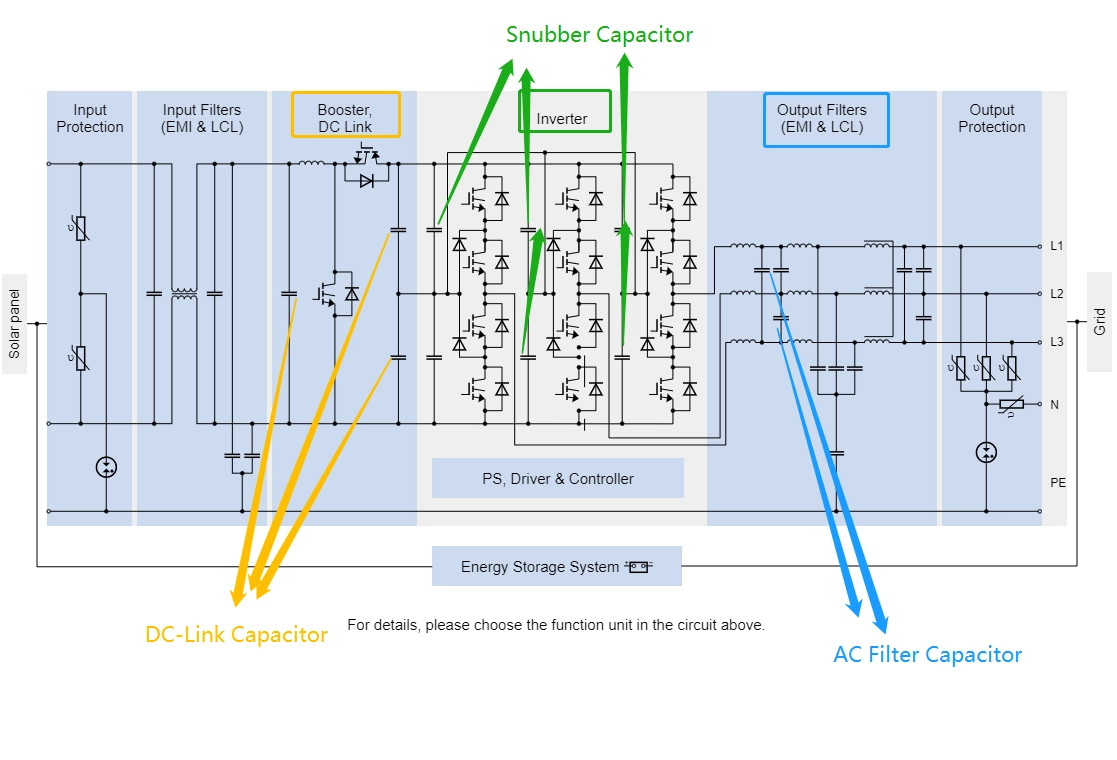

In power systems, capacitors with DC sources are great for smoothing things out. After AC gets turned into pulsing DC, capacitors fix voltage ups and downs. They charge up during high points and release during low points. This gives steady voltage for delicate devices. Used in DC-Link circuits, can replace electrolytic capacitor. Low ESR, high ripple current handling capabilities—these make capacitors perfect for filtering in renewable energy or factory drives.

Capacitors let AC signals pass between amplifier stages while stopping unwanted DC parts. In decoupling, they keep power lines steady. They soak up sudden current spikes from switching parts like microcontrollers or digital chips. When placed across power rails in DC circuits, these capacitors cut noise and stop voltage drops that could mess up gear.

Capacitors bring safety and steadiness to DC circuits. They grab an extra charge to block sudden voltage jumps that could hurt parts. Also, the rated voltage (WV) should be the safe limit. This keeps things running smoothly. In high-voltage setups like electric vehicles or grid converters, picking the right capacitors ensures they last and stay cool.

In wind turbines and solar PV systems, capacitors in DC links are super important. They keep voltage steady when power changes. Used in inverters of wind power and solar power, these parts handle tough conditions. For example, big solar farms use film-based capacitors in inverters. They manage high ripple currents and last long outside.

Electric vehicles need power electronics for motors and batteries. Capacitors with high ripple current capability smooth voltage from chargers or braking systems. Transportation: EV or HEV applications need small, tough solutions for rough conditions. Fast-charging stations use these in rectifier units to keep voltage steady across many ports.

Capacitors are everywhere in phones, laptops, wearables, and smart home gadgets. These run on USB or battery packs with steady DC voltage. Low ESR capacitors clean up noise that could mess with wireless signals or chips. As IoT grows in smart grids and cities, steady power is key for millions of devices.

Factories use PLCs, servo drives, motor controllers, and robotic arms. These need reliable power filtered by capacitors. They handle changing loads. Long lifetime capacitors cut downtime and repair costs. In robotics with fast moves or vision units, low ESR designs keep signals clear during quick cycles.

SMILER makes awesome film capacitors for tough fields like renewable energy, transportation, automation, and big projects. Our modern production lines churn out 300,000 units a day with a 99.93% pass rate. State-of-the-art automated facilities ensure efficiency, precision, and consistency throughout manufacturing processes.

Low ESR, high ripple current handling capabilities make SMILER's film capacitors work great under heavy switching. They're perfect for fast-charging EV stations or grid converters.

Super low equivalent series resistance (ESR) keeps things cool. This stops overheating, a big issue in high-frequency switching.

Self-healing metallized polypropylene film construction is a game-changer. Self-healing property lets capacitors recover from small breakdowns without failing. This makes them last long in renewable setups or factory panels.

Aluminum shell packaging with resin potting makes them small. They fit tight spaces on PCBs in embedded systems without losing performance.

All SMILER products meet tough standards like IEC 61071 for pulse-load performance. Operating Temperature Range D≤116mm: -40˚C;~ 85˚C ensures they work in cold Nordic areas or hot equatorial zones. They're ready for strict global green rules on electronics.

Q: Why does a capacitor block direct current after being fully charged?

A: When fully charged, no more current flows through the dielectric. There's no voltage difference left, so it acts like an open circuit.

Q: Can I use any type of capacitor with a DC source?

A: Nope. Pick ones rated for your voltage and ripple needs. Film capacitors often beat electrolytics in steady loads due to low ESR.

Q: How do I determine if my capacitor has aged prematurely?

A: Look for higher ESR or lower capacitance. Running way below rated voltage can cause issues and cut ripple handling. When the electrolytic capacitor works at a voltage far below the rated working voltage...it will lead to polarization...and reduce the ripple current.

Q: Are there risks associated with overvoltage on a capacitor?

A: Yup. Going over surge ratings can build pressure and cause a rupture. Rated surge voltage is the maximum DC overvoltage that the capacitor may withstand at 25°C.

Q: What makes low ESR important when choosing a capacitor? A: Low ESR cuts heat during use. This boosts efficiency and makes capacitors last longer, especially in fast-switching electronics.