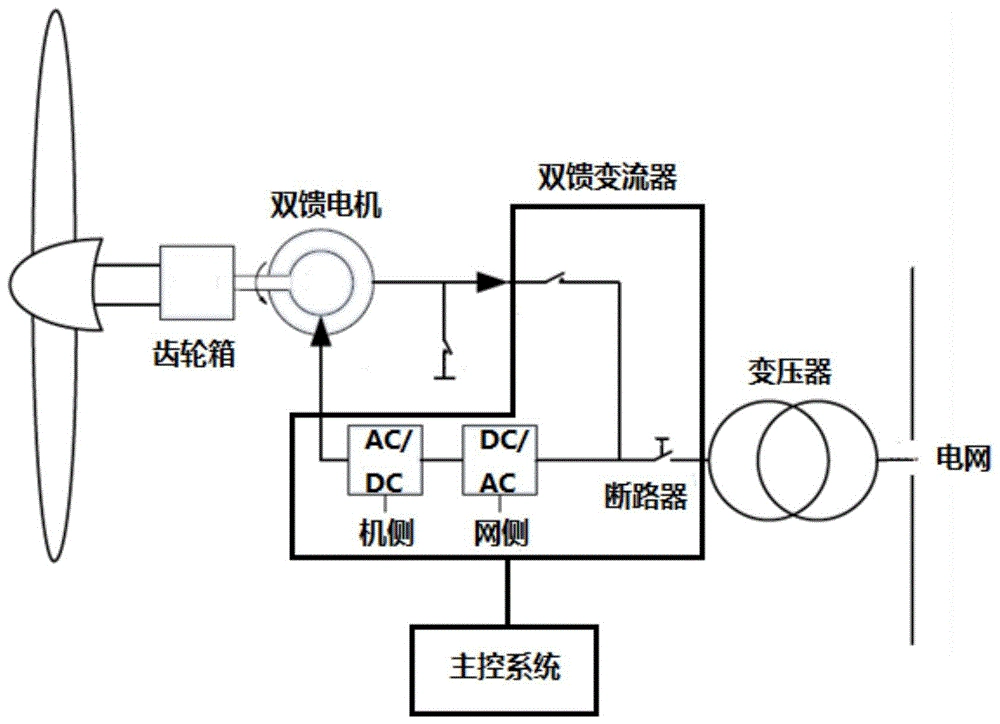

Wind turbines turn wind energy into stable AC power for the grid. The inverter is key to this process. It changes DC from the turbine's generator into AC. This needs precise control and strong parts to work well and stay reliable.

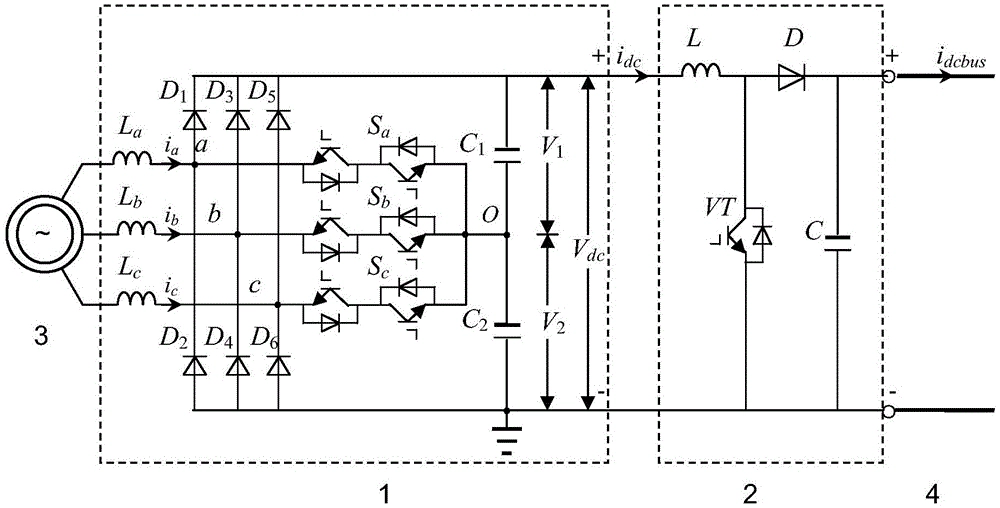

Capacitors are used in important spots like the DC link, output filters (LC and LCL), and snubber circuits. They keep voltages steady, reduce noise, and control energy flow. In wind power systems, capacitors are vital in places like DC Link Inverter Output Filters (LC&LCL) to ensure smooth operation.

Wind farms, especially offshore ones, face tough conditions like salt spray, humidity, big temperature swings, and vibrations from turbine motion. These factors wear out parts faster.

Capacitors in nacelles or near power electronics must work with these stresses without failing. If they don't, it can cause system shutdowns or serious equipment damage.

Thermal resistance is important in tight spaces like nacelles, where cooling is limited. Self-healing metallized film technology lets capacitors recover from small breakdowns without losing function. This extends their life a lot.

SMILER's MKP-AL Series AC Filter Capacitor (Cn: 3x8μF~3x335μF, Vn: 230V~850Vac) offers nice thermal performance. It works as an output filter, reducing harmonic distortions and electromagnetic interference (EMI) for smoother operation under varying loads. Capacitors also support reactive power compensation and harmonic filtering, which are key for grid stability.

Capacitor failure can disrupt the whole inverter system. Choosing parts with high ripple endurance, self-healing features, and strong insulation extends maintenance cycles and lowers downtime risks.

A European onshore wind project showed this. After using SMILER MKP-LL DC Link capacitors, operators saw a 40% drop in unscheduled maintenance over two years. This was due to better thermal stability and ripple handling.

Wind turbine inverters often work at high voltages due to large energy needs. Capacitors rated up to 7000Vdc ensure safe operation during peak loads.

Ripple currents cause internal heating. If capacitors can't handle them, they fail early. SMILER's products use enhanced foil designs to spread heat well under high-ripple conditions.

Capacitors must survive temperature changes without wearing out. Metallized film types, like SMILER's, have self-healing features that fix small faults while keeping performance. This is vital for remote wind farms where maintenance is hard.

Offshore sites need capacitors with high corrosion resistance due to salty air. Encapsulation materials must block moisture while keeping dielectric strength over the years.

Onshore sites deal with bigger temperature changes but less humidity stress. Here, thermal shock resistance is more important than salt protection.

High-altitude sites have less air density, which reduces cooling efficiency. Capacitors with better heat dissipation are key. In tropical areas, moisture-resistant encapsulation prevents dielectric breakdown from condensation or salt deposits.

Yes—better capacitors increase uptime and cut maintenance needs. This boosts system availability for wind turbines and other renewable platforms like solar PVs.

Reliable parts lower lifecycle costs and maximize clean energy output per dollar spent. This supports the growth of wind and solar as key parts of the energy transition.

Inverters connect renewable sources to utility grids. Their health affects grid quality through harmonic suppression, reactive power compensation, and voltage regulation—all supported by high-performance capacitors.

Reducing reactive power and improving power quality saves costs and ensures steady operation for power generators and users in low- and medium-voltage grids.

Long-life parts cut total ownership costs, a key factor for utility-scale projects with tight budgets. As global demand for renewables grows, utilities want film capacitors with over 100,000 hours of service life under full load. SMILER's MKP series meets this benchmark for DC link, snubber, and AC filter applications.

SMILER focuses only on capacitors for industrial uses like wind energy systems, solar energy storage, UPS systems, and EV drives. This narrow focus builds deep expertise, ensuring top-quality products.

SMILER has supplied reliable and durable parts for this market for years, earning trust worldwide.

The MKP-LL Series offers a long lifespan under the constant load cycling of variable-speed wind turbines. Enhanced foil patterns spread heat well, improving durability.

Space is tight in nacelles atop tall towers. SMILER's compact capacitors deliver strong performance without taking up much room, ideal for OEM designs or retrofits.

Self-healing dielectric layers allow continued operation after small breakdowns. This is critical for offshore turbines, where repair costs are much higher than onshore ones.

At the 2024 Vietnam International Electronics & Smart Appliances Expo, SMILER showed its latest capacitor solutions for renewable sectors. Major players like SUNHOUSE Group now use our products after seeing their technical strength firsthand.

Q: What type of capacitor is best suited for DC link applications in wind turbine inverters?

A: Metallized polypropylene film capacitors, like SMILER's MKP-LL Series, are ideal. They offer high voltage tolerance (up to 7000Vdc), low ESR, strong ripple current handling, and long life under constant loads.

Q: How do environmental factors affect capacitor selection in wind turbines?

A: Humidity, extreme temperatures, altitude, salt spray (offshore), or dust (onshore) influence material choices. Encapsulation and thermal management features are needed to work with these conditions.

Q: Why is ripple current capability important when selecting an inverter capacitor?

A: Ripple currents cause internal heating. Poor handling leads to early failure. High ripple endurance ensures stable operation during fast switching in IGBT-based converters.

Q: Can using better capacitors improve overall system reliability?

A: Yes—high-quality film capacitors extend inverter life by working with electrical stress and reducing failures from transient spikes or thermal fatigue in variable load settings.

Q: Are there specific standards or certifications required for capacitors used in renewable energy systems?

A: Standards like IEC61071 are common. Most projects require endurance tests for temperature cycling (>85°C), voltage withstand (>2x rated Vdc), and partial discharge thresholds to ensure reliability.